Wholesale Price Nanrong 120t used Injection Molding Machine Export to Philadelphia

Wholesale Price Nanrong 120t used Injection Molding Machine Export to Philadelphia Detail:

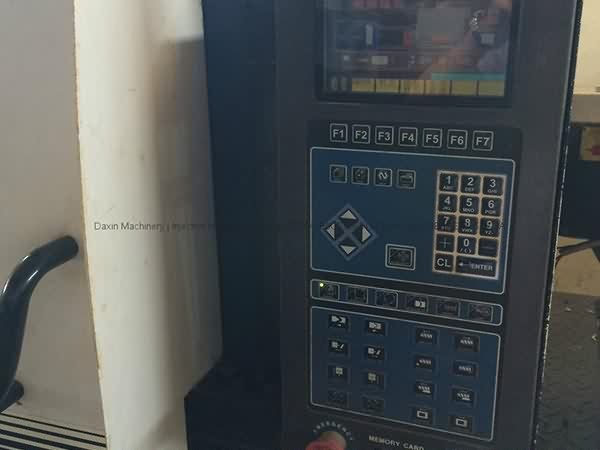

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for Wholesale Price Nanrong 120t used Injection Molding Machine Export to Philadelphia, The product will supply to all over the world, such as: Bulgaria , Boston , Philippines , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Fully-automatic PET Bottle Blow Molding Machine adopt Siemens PLC & Touch Screen,Germany Festo pneumatic system,Japan Mitusbishi Servo Motor ,high ...

Малогабаритный термопластавтомат для домашнего применения.

Вес отливки - до 4г.

Напряжение питания - 220В.

Потребляемая мощность - менее 1кВт/ч.

Пиковая нагрузка по току - 12А.

Харьков, Украина

kpdplast@mail.ru

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!