Wholesale Price Niigata 180t used All-electric Injection Molding Machine to Berlin Importers

Wholesale Price Niigata 180t used All-electric Injection Molding Machine to Berlin Importers Detail:

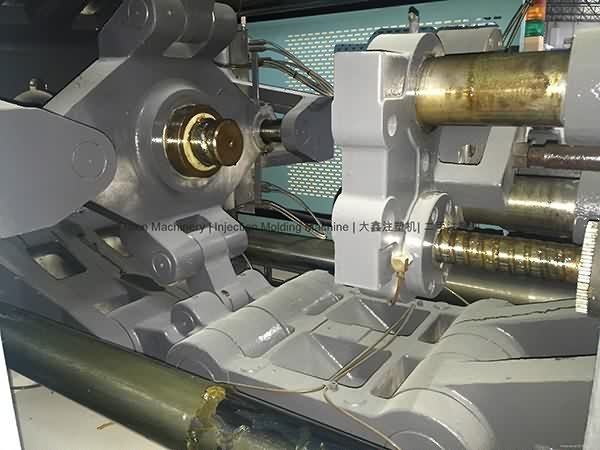

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Wholesale Price Niigata 180t used All-electric Injection Molding Machine to Berlin Importers, The product will supply to all over the world, such as: South Korea , El Salvador , Madras , Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

PET Preform Injection Machine FROM China Evertopmachine

https://www.evertopmachine.com/

https://www.evertopmachine.com/water-filling-machine/

https://www.evertopmachine.com/carbonated-beverage-filling-machine/

https://www.evertopmachine.com/juice-tea-hot-filling-machine/

https://www.evertopmachine.com/barreled-drink-water-filling-machine/

https://www.evertopmachine.com/glass-bottle-filling-machine/

https://www.evertopmachine.com/can-filling-machine/

https://www.evertopmachine.com/oil-filling-machine/

https://www.evertopmachine.com/milk-filling-machine/

https://www.evertopmachine.com/wine-filling-machine/

https://www.evertopmachine.com/labeling-machine/

https://www.evertopmachine.com/water-treatment-system/

https://www.evertopmachine.com/blow-moulding-machine/

https://www.evertopmachine.com/injection-moulding-machine/

https://www.evertopmachine.com/automatic-bottle-packing-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-packing-machinery/

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!