Wholesale Price Sumitomo 130t All-Electric used Injection Modling Machine for Tajikistan Factory

Wholesale Price Sumitomo 130t All-Electric used Injection Modling Machine for Tajikistan Factory Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

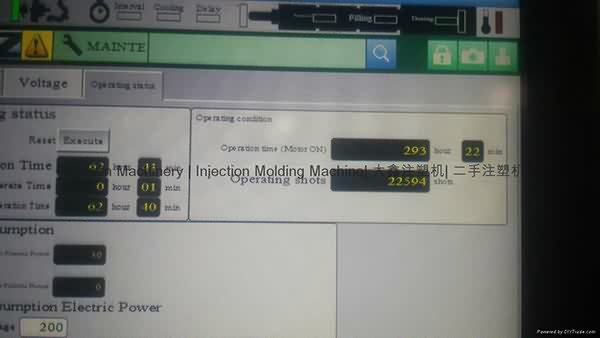

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Wholesale Price Sumitomo 130t All-Electric used Injection Modling Machine for Tajikistan Factory, The product will supply to all over the world, such as: Hyderabad , Bahamas , Madagascar , The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

High speed toothbrush making machine(Two color) with high quality and best price.

flip top cap mould testing in SINOMOLD www.sinomould.com PP cap mold.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.