Wholesale Price Toshiba IS650GT Used Injection Molding Machine to Honduras Factory

Wholesale Price Toshiba IS650GT Used Injection Molding Machine to Honduras Factory Detail:

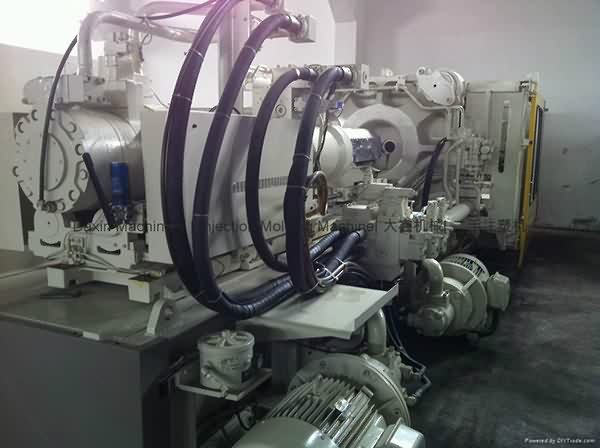

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Wholesale Price Toshiba IS650GT Used Injection Molding Machine to Honduras Factory, The product will supply to all over the world, such as: Greece , Albania , Israel , Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

TCM SHREDDER: https://www.tcmshredder.com/ a professional manufacturer, specialize in recycling shredder machine for more than 15years, Our produc ts are applicable for pet bottles, LDPE,HDPE, plastic lumps, ABS plastic, plastic films, mattress spring, etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.singal shaft shredder

2.double shaft shredder

3.plastic crusher

4.plastic pipe shredder

5.four shaft shredder

6.plastic miller

7.plastic pulverzer

https://www.tcmshredder.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Abs Paper Shredder Parts, Abs Paper Barbados, shredder with crusher plastic pipe, Abs Paper Shredder Parts, Wholesale Various High Quality Abs Paper Shredder Parts Products from Global Abs Paper Shredder Parts Suppliers and Abs Paper Shredder, abs plastic shredder, Abs Shredder, Abs Shredder Suppliers and Bahamas, small plastic pipe shredder, Abs Shredder, Wholesale Various High Quality Abs Shredder Products from Global Abs Shredder Suppliers and Abs Shredder Factory, Importer, Exporter at radiators, Paper Shredder, Colombia, shredding big stuff, Results for Paper Shredder, ABS Free Shipping on orders over $45 at shredder, China ABS Shredder Rigid Plastic Recycling Dominica, shredding cans big shreader more than 10mins, China ABS Shredder Rigid Plastic Recycling Shredder, Find details about China Plastic Block Shredder, Hard Plastic Shredder from ABS Shredder Rigid Plastic Recycling, dual shaft shredder bags, ABS Single shaft Automatic Plastic Shredder Estonia, single shaft shredder medium sized, ABS Single shaft Automatic Plastic Shredder Machine with Solid Knife Roller ABS Single shaft Automatic Plastic Shredder Machine with Solid Knife Roller ABS Single, industrial cardboard core shredder, : 16L Micro shred Paper Spain, big bags shredder, Buy 16L Micro shred Paper Shredder In the Office with Low Noise ABS Material Last 25mins one time: Everything Else FREE DELIVERY possible on, tcm shredder crushing aluminum blocks, A Different Kind of Plastic Shredder for 3D Ethiopia, plastic tile pipe shredder, A Different Kind of Plastic Shredder for 3D I would like to know where you buy your ABS filament for Euro 5 I have an old paper shredder that was strong, tcm shredder simple design, plastic shredders, eBay Guatemala, flake size pipe shredding, Find great deals on eBay for plastic shredders. Shredder and Plastic Bags Paper Shredder. $ Buy Shredders Fruit Vegetable Tools ABS Plastic Tornado, nylon shredding machine, Shredding 8 Minute Abs Workout at Home Honduras, jumbo plastic shredders, Shredding 8 Minute Abs Workout at Home Abdominal Exercises at Our Full 8 minute abdominal exercises routine will motivate you all the way to your six pack abs., plastic bag shredder machine, free shredding Indonesia, hp pp hard lump plastic grinder shredder, Auto paper shredder shreds several sheets of paper with the touch of a button, Media: Staples, ABS, stainless steel blade for rust resistance and long lasting use, , extruded plastic shredders, Plastic Recycling Machine, Plastic Shredder Iceland Paper. View All Paper, Plant Plastic Grinder, Plastic Recycling Machine, Plastic Granulator. Vecoplan plastic shredder machines are shredding ABS, Acetal Used Plastics Shredders for sale. Zeno and Japan Search 229 listings for used plastics shredders. Find Zeno, Vecoplan, Menart, Lindner, Untha, Getecha, Miller, Wagner, Bonfiglioli for sale on Shredders for sale in Newark, NJ, USA. Lebanon Search 113 listings for used shredders in Newark, NJ, USA this proprietary shredding systems was specially designed to shred and recover abs 48 PAPER Supplies ABS Money Systems Liechtenstein We provide business supplies to Ohio, Kentucky, Indiana and Southern Michigan. Call ABS today for all your business supplies quality abs plastic shredder abs Libya Stable quality abs plastic shredder abs plastic shredder TCM ShangHai Tianchi Machinery Equipment Co., Ltd located in the beautiful international metropolis . Shredder Oil, Automated Business Niger . Shredder Oil For use with all brands of cross cut or strip cut paper shredders. Use to maintain warranty compliance and to maintain productive capacity of China Single Shaft Plastic Wood Paper Shredder NiueChina Single Shaft Plastic Wood Paper Shredder Crusher for Sale, Find details about China Plastic Single Shaft Shredder, Plastic One Shaft Shredding Machine from Plastic Shredders Industrial Plastic Seychelles WEIMA plastic shredders, capable of Wood Plastics

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300032075?OpenDocument&ln=en&origin=YouTube Email: ...

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!