100% Original Nanrong 250t used Injection Molding Machine for Lyon Manufacturers

100% Original Nanrong 250t used Injection Molding Machine for Lyon Manufacturers Detail:

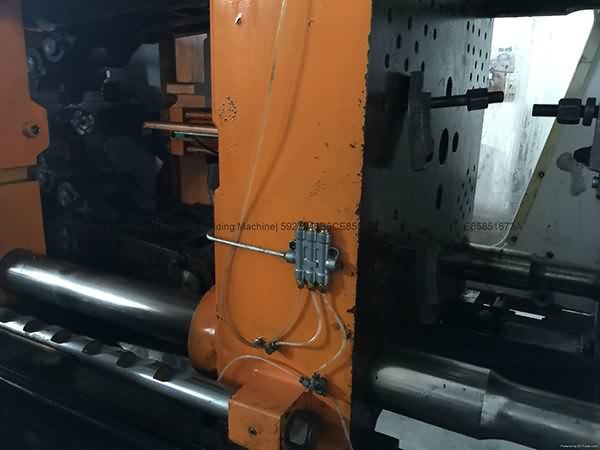

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for 100% Original Nanrong 250t used Injection Molding Machine for Lyon Manufacturers, The product will supply to all over the world, such as: Slovenia , Manila , Gabon , We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

nhận sửa khuôn thiết kế chế tạo khuôn ép nhựa. gia công chế tạo chi tiết máy móc cơ khí chính xác cnc1st.com ceocnc1st@gmail.com Chuyên nhận gia công, ...

Miles travels through Amish country while Bob tries to understand Miles weird neighbors. Come see Flat Manny, the amazing paper mail carrier! It's finally here ...

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.