2017 wholesale price JSWJ1300EIII used Injection Molding Machine to Australia Importers

2017 wholesale price JSWJ1300EIII used Injection Molding Machine to Australia Importers Detail:

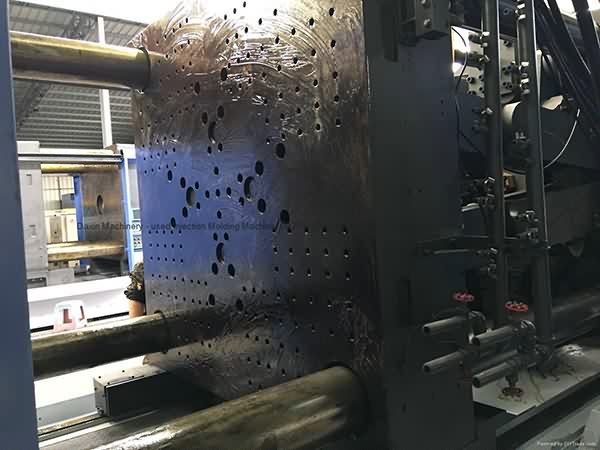

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for 2017 wholesale price JSWJ1300EIII used Injection Molding Machine to Australia Importers, The product will supply to all over the world, such as: Comoros , Malawi , Spain , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Gelong industries

www.gelongindustries.com

Manufactures & Traders of-DALL, BESAN, FLOUR MILL MACHINERY.

A 15 vikas vihar, chander vihar, nilothi ext. Part 3. New Delhi

Mobile number 09911401311, 09868241884, 8800341233

For videos type (gelong.in)in YouTube

Email address :- gelongindustries@gmail.com

small besan plant

raw material for besan plant

mini besan plant project report

besan plant video

mini besan mill project report

besan pulverizer

rajdhani besan plant

besan manufacturers in indore

besan manufacturing process

price of besan per kg

besan wholesale price

besan mill plant cost

rajdhani besan 1kg price

dal mill plant in india

dal mill process

dal mill business

rice mill

Watch this video to see how the latest MAGMASOFT® metal flow simulation technology enables RCM’s engineers to determine the best process parameters for ensuring part quality.

Before production, our simulation experts use RCM’s industry leading gate and runner design techniques to determine the best point to inject molten metal into a die, ensuring you receive finished parts with the best density and structural features possible.

Discover More @ RCMIndustries.com

Call 847-455-1950

Email us at sales@rcmindustries.com

Subscribe for more videos!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.