Short Lead Time for Mitsubishi 1300t Used Injection Molding Machine to Poland Factory

Short Lead Time for Mitsubishi 1300t Used Injection Molding Machine to Poland Factory Detail:

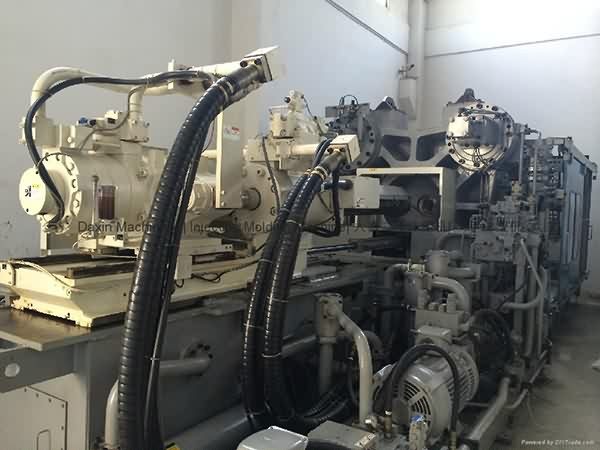

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for Short Lead Time for Mitsubishi 1300t Used Injection Molding Machine to Poland Factory, The product will supply to all over the world, such as: Ghana , Greek , Honduras , We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity

https://plastiwin.com/equipment-brands-we-offer/ Used 337 Ton Battenfeld EcoPower 300 All Electric Injection Molding Machine:

* Brand: Battenfeld

* Model: EcoPower 300

* Tonnage (Metric/US): 300/337

* Year of Mfg.: 2013

* Screw Diameter: 65mm

* Shot Size: 29 oz. (PS)

* Tie Bar Spacing: 30.3" x 28.35"

* Mold Height (Min/Max): 13.78" x 29.5"

* Injection Pressure: 21131

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!