Chinese Professional Sumitomo 130t All-Electric used Injection Molding Machine to Mauritius Factory

Chinese Professional Sumitomo 130t All-Electric used Injection Molding Machine to Mauritius Factory Detail:

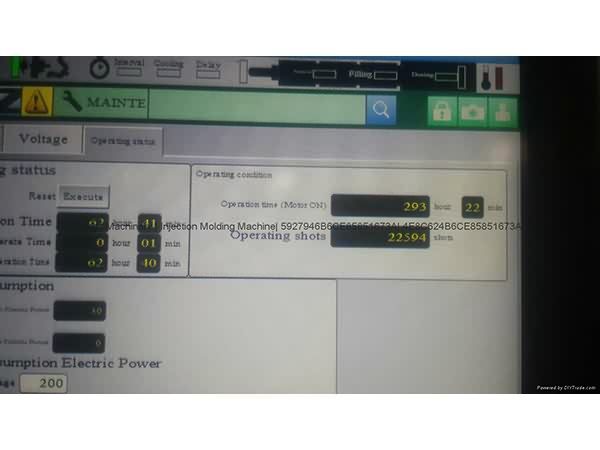

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Chinese Professional Sumitomo 130t All-Electric used Injection Molding Machine to Mauritius Factory, The product will supply to all over the world, such as: Mecca , Georgia , Japan , We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

20L Pail Forza PT450H Production Dry cycle

Máy ép nhựa Forza 450T ép thùng 20L (máy chạy không tải), với hệ thống dán nhãn bên trong IML, làm cho chu kỳ sản xuất ngắn hơn.

Liên hệ: 0909 725 216

The wood plastic composite WPC profile machine including SJMS 65/132 conical double screw extruder,mold,vacumm sizing platform,hual-off device,cutter,stacker. The machine can produce the WPC outdoor floor,decking,etc.The auxiliary equipment including wood milling machine,mixer,WPC granulating machine,cursher,sander,embosser,brushing machine.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.