Competitive Price for Haitian 250t (servo) used Injection Molding Machine for Vancouver Factory

Competitive Price for Haitian 250t (servo) used Injection Molding Machine for Vancouver Factory Detail:

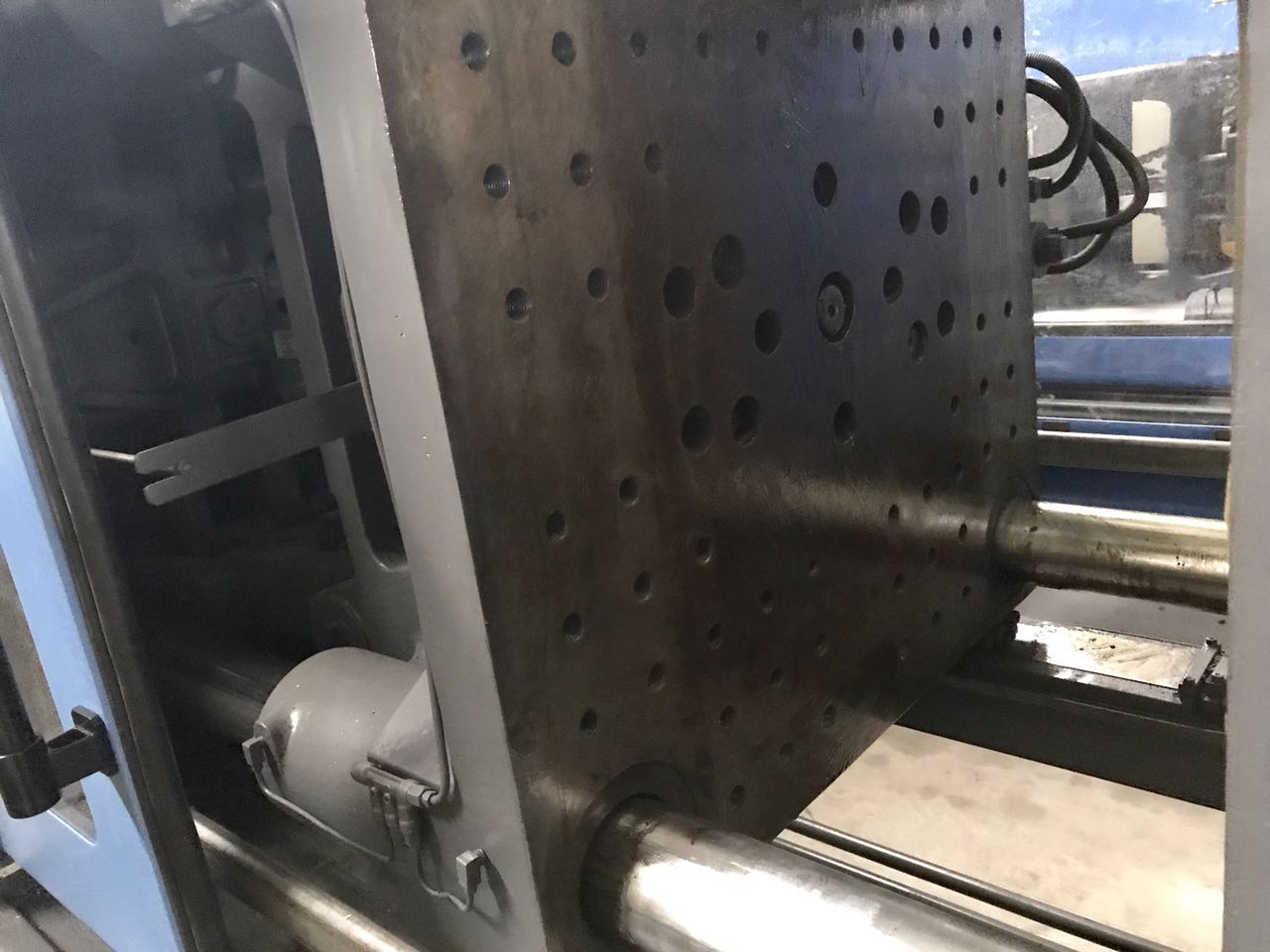

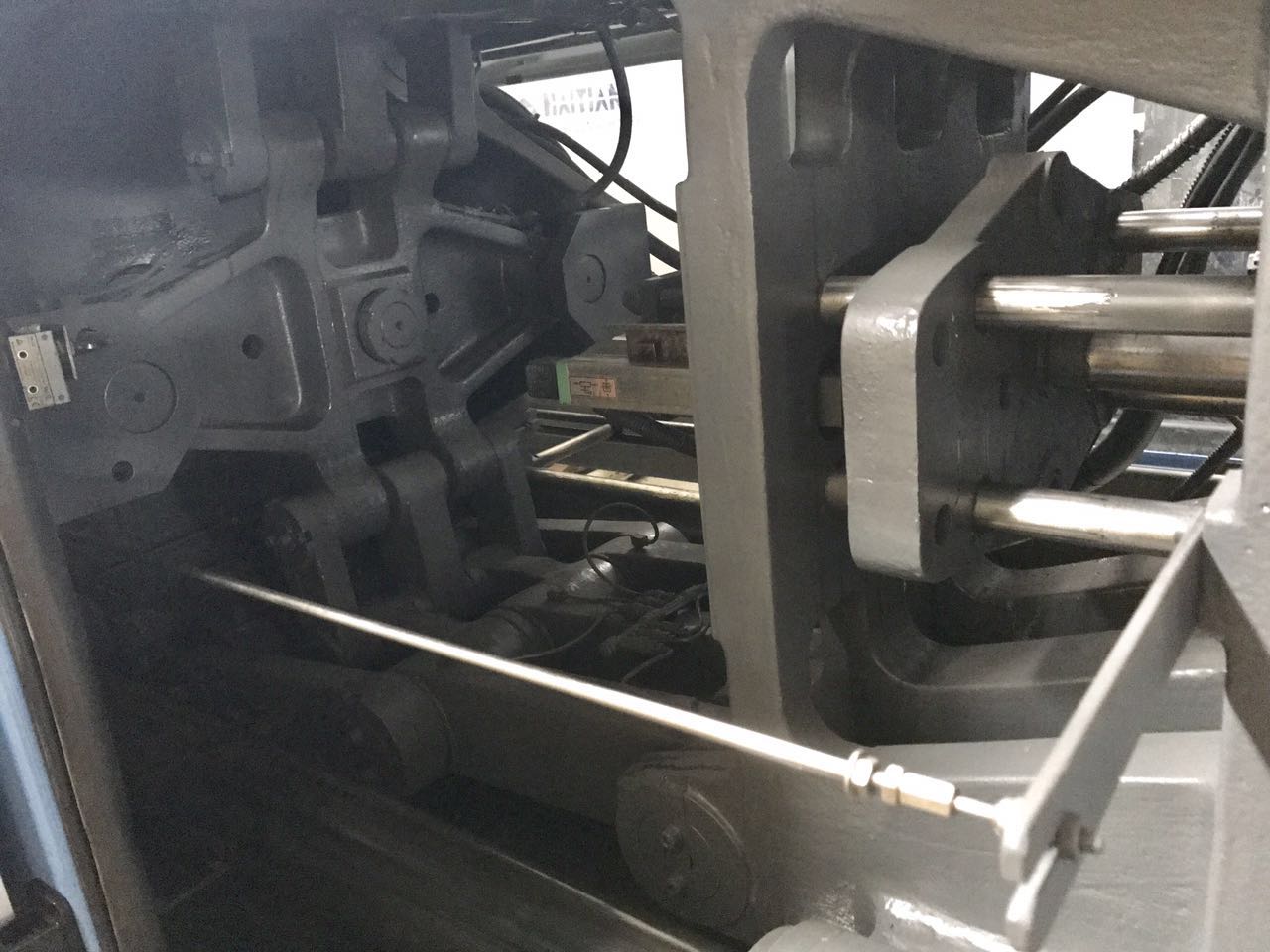

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for Competitive Price for Haitian 250t (servo) used Injection Molding Machine for Vancouver Factory, The product will supply to all over the world, such as: Uganda , Oman , Denmark , With the principle of win-win, we hope to help you make more profits in the market. An opportunity is not to be caught, but to be created. Any trading companies or distributors from any countries are welcomed.

Information about the Dorman Fuel Line Repair Kit, part number 800-300.

Fordern Sie bei Logismarket weitere Informationen an: https://www.logismarket.ch/storopack/schaumpolstermaschine/1428512601-699516362-p.html Foamplus ...

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.