Factory Price For Chen Hsong Super Master SM50 used Injection Molding Machine to Hongkong Manufacturers

Factory Price For Chen Hsong Super Master SM50 used Injection Molding Machine to Hongkong Manufacturers Detail:

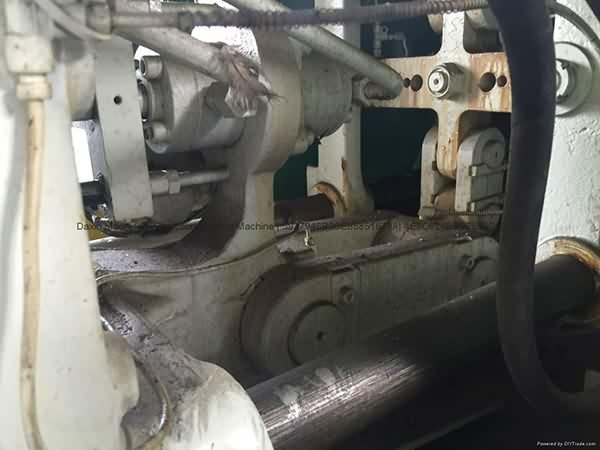

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

abide by the contract", conforms to the market requirement, joins in the market competition by its high quality as well as provides more comprehensive and excellent service for clients to let them become big winner. The pursue of the company, is the clients' satisfaction for Factory Price For Chen Hsong Super Master SM50 used Injection Molding Machine to Hongkong Manufacturers, The product will supply to all over the world, such as: Sudan , Sao Paulo , Bangkok , So far our products have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have 13years professional sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

welcome contact www.boyuplasticmachine.com

Jay ma whatsapp 8613814297981

boyuplast@qq.com

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.