Factory Promotional Chen Hsong Super Master SM50 used Injection Molding Machine to Mecca Manufacturer

Factory Promotional Chen Hsong Super Master SM50 used Injection Molding Machine to Mecca Manufacturer Detail:

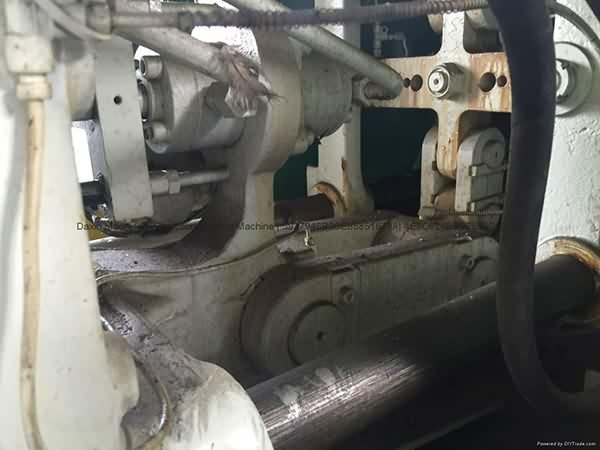

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We consistently carry out our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Factory Promotional Chen Hsong Super Master SM50 used Injection Molding Machine to Mecca Manufacturer, The product will supply to all over the world, such as: Mongolia , Indonesia , Jeddah , The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

Good day. This is John. From Hong Guan Machinery. With reference to the product offering on your site. May I know if you need a packaging machinery supplies ...

A small current controlled by an Arduino is being used to close the primary circuit of a relay. The relay, in turn, is using a nine volt battery on the secondary circuit ...

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!