Fast delivery Haitian 250t (servo) used Injection Molding Machine – Kawaguchi Used Injection Molding Machine

Fast delivery Haitian 250t (servo) used Injection Molding Machine – Kawaguchi Used Injection Molding Machine Detail:

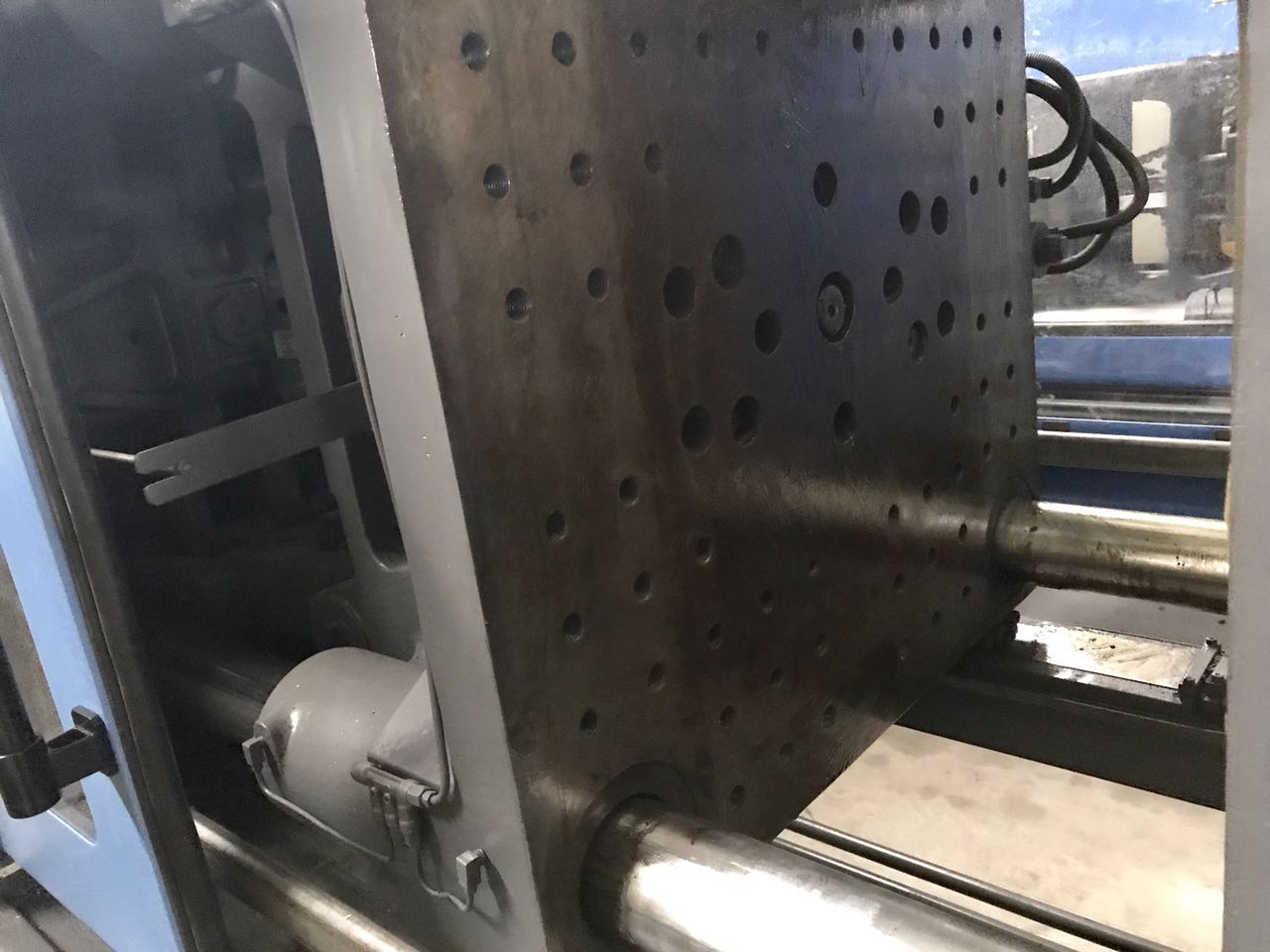

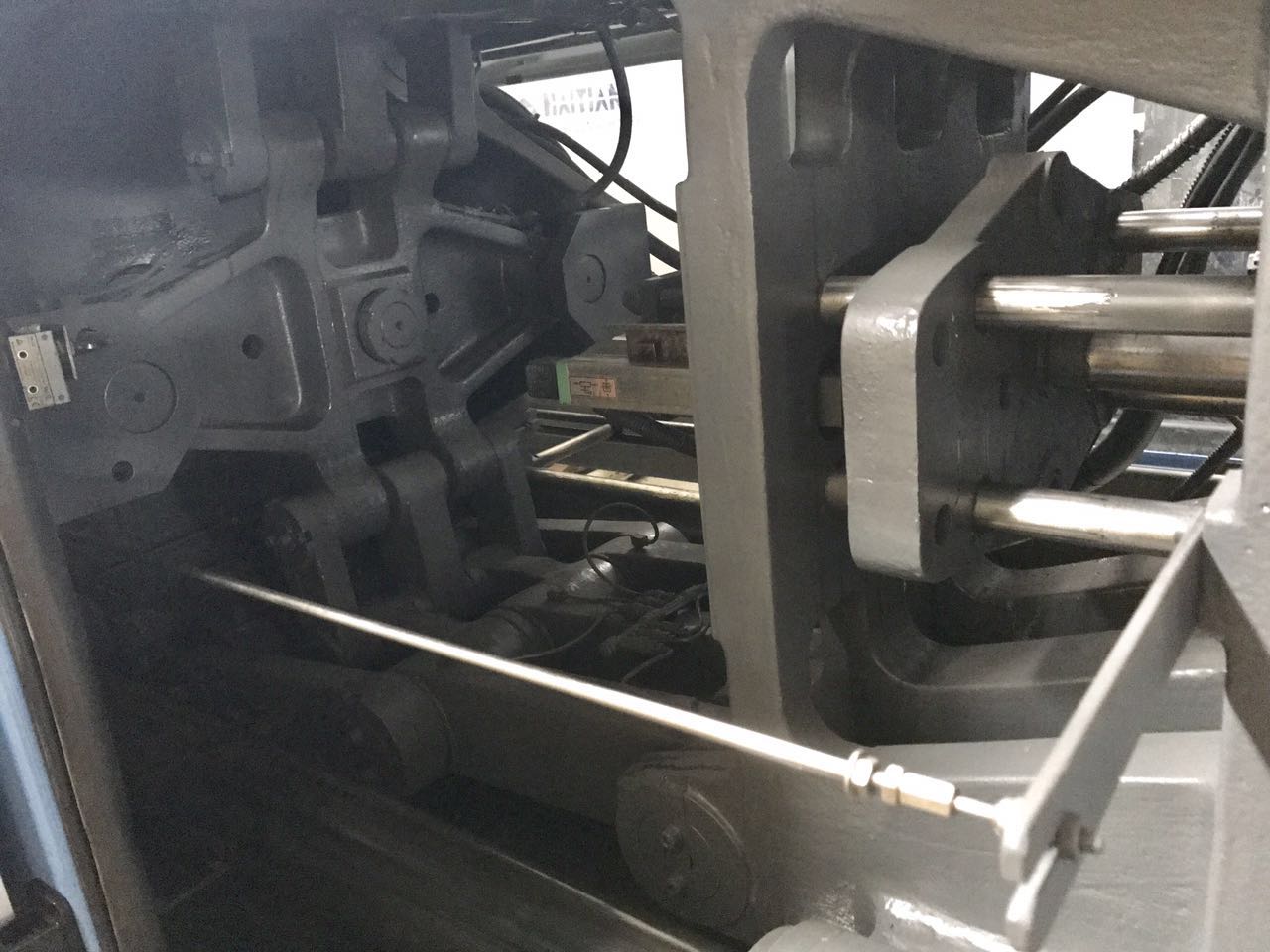

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for Fast delivery Haitian 250t (servo) used Injection Molding Machine – Kawaguchi Used Injection Molding Machine, The product will supply to all over the world, such as: Burundi , Nepal , Uzbekistan , Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

Welcome to Charmi Machinery Industries Pvt Ltd,

We are leading plastic machinery manufacturer based in Ahmedabad, Gujarat,

We Manufacture Horizontal Plastic Injection Molding Machine

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.