Free sample for CLF-200TY used Injection Molding Machines for South Korea Factory

Free sample for CLF-200TY used Injection Molding Machines for South Korea Factory Detail:

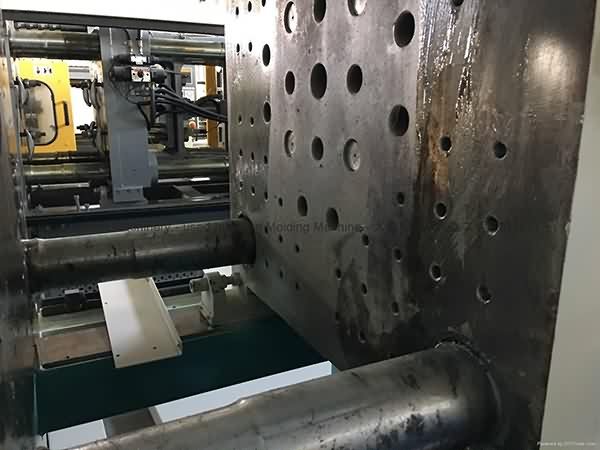

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for Free sample for CLF-200TY used Injection Molding Machines for South Korea Factory, The product will supply to all over the world, such as: Kuwait , Finland , Rwanda , We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034473?

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!