Good User Reputation for Chen Hsong Super Master SM50 used Injection Molding Machine to Las Vegas Factory

Good User Reputation for Chen Hsong Super Master SM50 used Injection Molding Machine to Las Vegas Factory Detail:

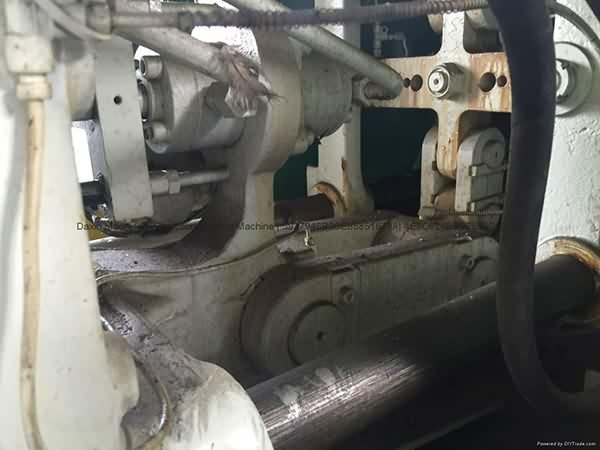

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Good User Reputation for Chen Hsong Super Master SM50 used Injection Molding Machine to Las Vegas Factory, The product will supply to all over the world, such as: Ukraine , Turkey , Paraguay , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Used Rajoo PP Film Machine. Plastic Film Extruder For Sale In Karnataka

Double Shot injection or 2K moulding is referring to injection 2 material at the same time. This technique will help to save some assembly jobs.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!