Hot Sale for Hwa Chin 160t two-color used Injection Molding Machine Export to Israel

Hot Sale for Hwa Chin 160t two-color used Injection Molding Machine Export to Israel Detail:

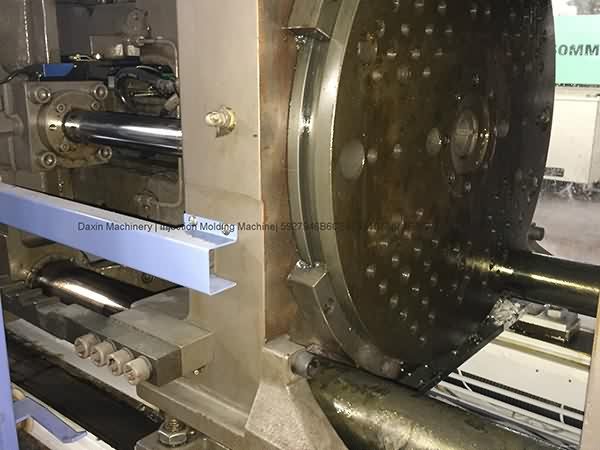

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Our improvement depends on the superior equipment, excellent talents and continuously strengthened technology forces for Hot Sale for Hwa Chin 160t two-color used Injection Molding Machine Export to Israel, The product will supply to all over the world, such as: Colombia , Montpellier , Honduras , We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

2001 Nissei Electric, IMM, Injection Molding Machine, 45 Ton, 1.6 oz.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!