OEM Customized Hwa Chin 160t two-color used Injection Molding Machine to Honduras Factories

OEM Customized Hwa Chin 160t two-color used Injection Molding Machine to Honduras Factories Detail:

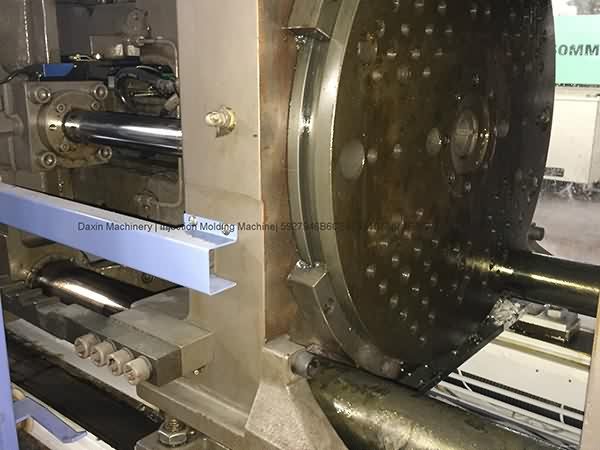

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for OEM Customized Hwa Chin 160t two-color used Injection Molding Machine to Honduras Factories, The product will supply to all over the world, such as: Sheffield , Thailand , Belize , High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Jet Engine Automation Co., Ltd. www.jetrobot.com.tw.

https://www.robotdigg.com/product/657/Digg-Desktop-Injection-Molding-Machine asliu@robotdigg.com.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.