PriceList for Haitian 160t used Injection Molding Machine Wholesale to Swedish

PriceList for Haitian 160t used Injection Molding Machine Wholesale to Swedish Detail:

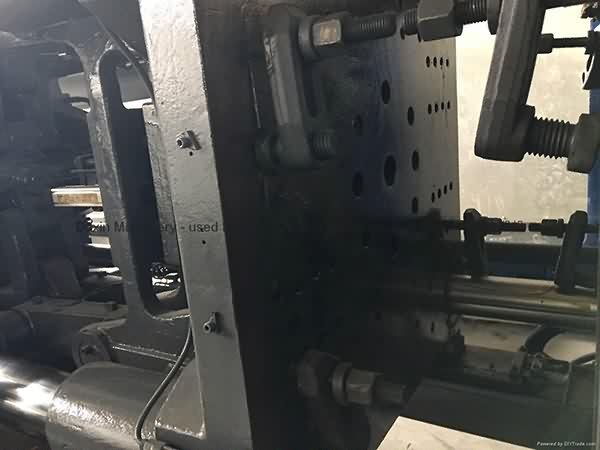

Haitian 160t used Injection Molding Machine

Model: SA1600/540v.

Year: 2010.

Screw: B-D38.

Tie bar spacing: 460mm.

Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of PriceList for Haitian 160t used Injection Molding Machine Wholesale to Swedish, The product will supply to all over the world, such as: Cairo , Iran , Israel , During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Giken Sakata (S) Limited - Japanese

https://www.karmasan.com

https://www.karmasan.net

shoe soles injection machines

shoe sole machine

shoe sole molding machines

shoe sole injection moulding machines

shoe sole injection molding machine

shoe sole injection machine

injection machine

injection moulding machines

injection molding machines

injection moulding machines price

shoe sole injection molding machines video

shoe sole injection machines

shoe sole injection moulding machine

shoe sole injection molding machine

shoe sole making machine

Injection Molding Machinery

shoe sole cleaning machine

types of shoe soles

shoe soles for sale

durable shoe soles for sale

shoe soles wholesale

glue for shoe soles

shoe sole material

Thermo PVC

TPU Tr PVC

types of shoe soles

shoe soles for sale

sole machines

shoe sole moulding machine manufacturer

shoe soles for making shoes

durable shoe soles for sale

shoe soles wholesale

shoe sole material

injection molded shoes

pu molding process

shoe sole manufacturers

shoe sole rubber sheet

good quality shoe sole

thermoplastic materials

shoe sole machine

extrusion system

shoe sole repair

shoe sole buy

injection system

high-quality soles

shoe sole for high heels

shoe sole for sale

Problems can be quickly and effectively resolved, it is worth to be trust and working together.