PriceList for JSWJ150EIII used Injection Molding Machine to Amman Factories

PriceList for JSWJ150EIII used Injection Molding Machine to Amman Factories Detail:

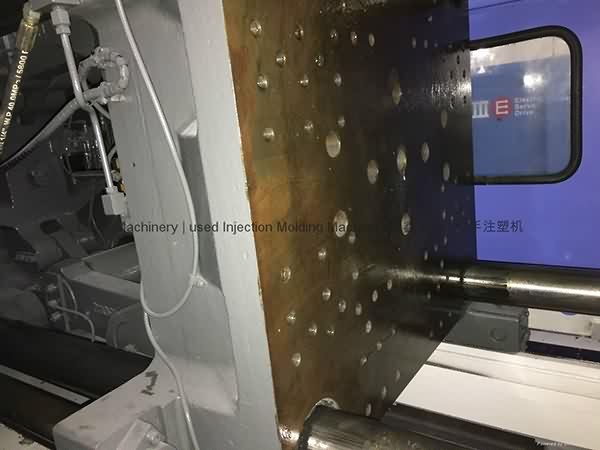

JSWJ150EII used Injection Molding Machine.

Model: JSWJ150EIII.

Year: 2006.

Screw diameter: 46mm.

Tie bar spacing: 510x510mm.

Machine is in very good running condition. Interested customer please visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for PriceList for JSWJ150EIII used Injection Molding Machine to Amman Factories, The product will supply to all over the world, such as: Angola , Albania , Malaysia , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

house/commercial multifunction sealers ,vacuum plastic Packaging Machine , packager for food

Buying Link :https://www.aliexpress.com/store/product/house-commercial-multifunction-vacuum-sealers-vacuum-plastic-Packaging-Machine-vacuum-packager-for-food/512038_1045780648.html

165 Ton Krauss Maffei Injection Molding Machine, Model KM150-460B2, 9 oz 1992 Vintage.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.