professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers

professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers Detail:

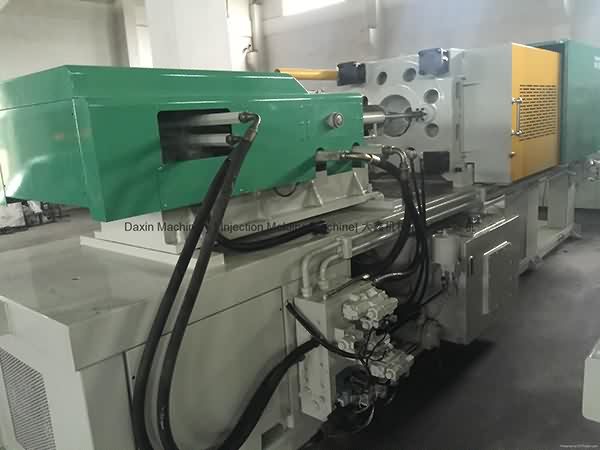

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value "unification, dedication, tolerance" for professional factory for Chen Hsong Super Master SM250TS used Injection Molding Machine for Florence Manufacturers, The product will supply to all over the world, such as: Malta , Manila , Sri Lanka , Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Plastic scrap - Briquette press machine test.

welcome contact www.boyuplasticmachine.com

Jay ma whatsapp 8613814297981

boyuplast@qq.com

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.