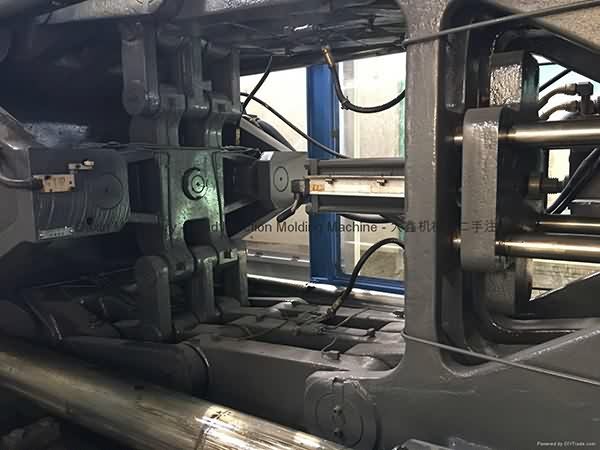

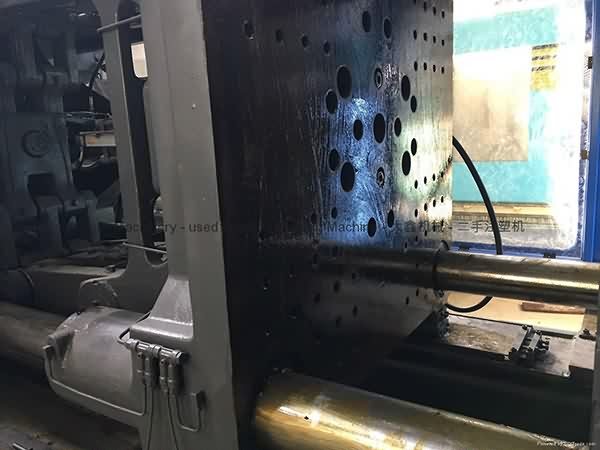

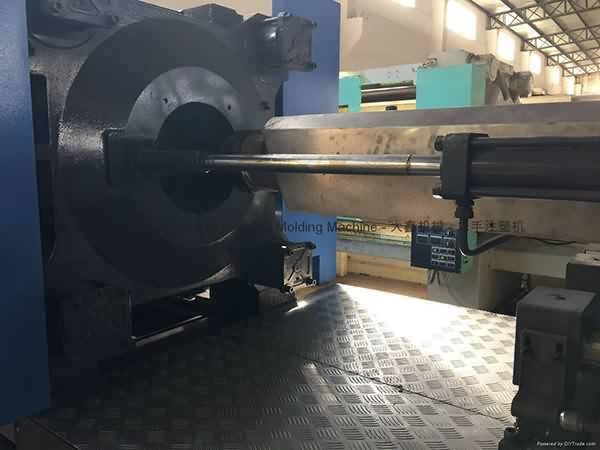

Quality Inspection for Haitian 380t used Injection Molding Machine for Estonia Factories

Quality Inspection for Haitian 380t used Injection Molding Machine for Estonia Factories Detail:

Haitian 380t used injection molding machine .

Model: SA3800/2250v.

Year : 2010.

Screw type: B-D70.

Tie bar spacing: 720x720mm

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Quality Inspection for Haitian 380t used Injection Molding Machine for Estonia Factories, The product will supply to all over the world, such as: Sydney , Iraq , Angola , We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.