Short Lead Time for Hwa Chin 160t two-color used Injection Molding Machine – CLF Plastic Machinery

Short Lead Time for Hwa Chin 160t two-color used Injection Molding Machine – CLF Plastic Machinery Detail:

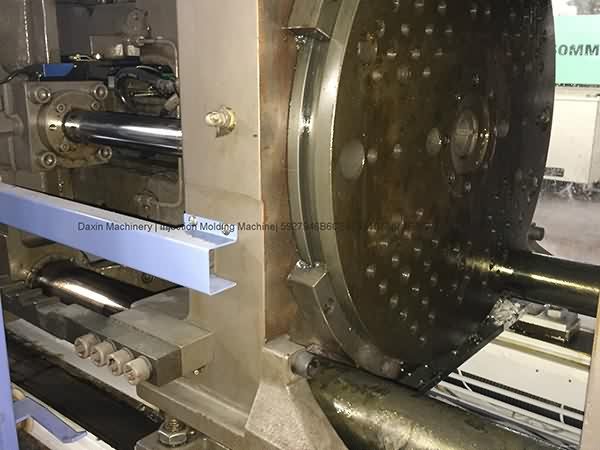

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Short Lead Time for Hwa Chin 160t two-color used Injection Molding Machine – CLF Plastic Machinery, The product will supply to all over the world, such as: Panama , Bolivia , Casablanca , We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, let us work together to get success.

แสดงขั้นตอนการใช้ เครื่องCNC Milling กัดขึ้นรูปชิ้นงาน ให้เป็น รูปทรงใบพัดของเครื่องจักรกล โดยวิธีการทำจะเริ่มตั้งแต่การออกแบบสร้างโมเดล3D ในโปรแกรม CAD/CAM เพื่อกำหนดตั้งค่าระยะพิกัดในการการกัดเจาะ ก่อน จากนั้นจึงนำวัสดุ ก็คือ ก้อน MC ไนลอน หรือ Pom สีดำ มาตัดให้ได้ตามขนาดและน้ำหนักที่กำหนด แล้วทำการจับยึดตั้งตำแหน่งชิ้นงานที่ฐานเครื่องCNC แล้วจึงสั่งเดินเครื่อง ไปจนเสร็จ

5 axis cnc mill | 5 axis machining | aluminum machining | c and c machine | c&c machine | c&c machining | cac machine | cc machine | cdc machine | cdc machines | cmc machine | cmc machines | cn machine | cna machine | cnc company | cnc fabrication | cnc lathe manufacturers | cnc machine companies | cnc machine manufacturers | cnc machine precision | cnc machine products | cnc machine shop | cnc machine stand for | cnc machining and manufacturing | cnc machining equipment | cnc machining inc | cnc machining prototype | cnc machining services | cnc machinist | cnc manufacturing | cnc manufacturing companies | cnc manufacturing process | cnc mill manufacturers | cnc milling company | cnc milling services | cnc plastic machining | cnc precision | cnc precision machining | cnc production | cnc production machining | cnc products | cnc router manufacturers | cnc router table | cnc routing service | cnc screw machine | cnc service | cnc shops | cnc swiss machine | cng machine | cnn machine | cns machine | computerized carving machine | computerized wood carving machine | custom cnc | custom cnc machining | custom cnc parts | custom machine shop | custom machined parts | custom machining | custom machining services | high speed machining | large machining | machine company | machine equipment | machine service | machine shop | machine shop tools | machine shop work | machined parts | metal machine | metal machine shop | ncn machine | online cnc machining | online machine shop | precision cnc | precision cnc machining | precision cnc milling | precision machine shop | precision machining | production cnc | production machine | prototype machine shop | prototype machining | screw machining | shop cnc machine | small c and c machine | swiss cnc | swiss machine | tnc machine | turning machine | used machine shop equipment | used machining centers | vertical cnc | vertical machine | wood c and c machine

TEDERIC MACHINERY CO.,LTD Add: No 245 North Wenze Road,Hangzhou Economic&Technological Development Area, China P.C.: 310018 Tel: ...

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.