Super Purchasing for Sumitomo 130t All-Electric used Injection Modling Machine Export to Georgia

Super Purchasing for Sumitomo 130t All-Electric used Injection Modling Machine Export to Georgia Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

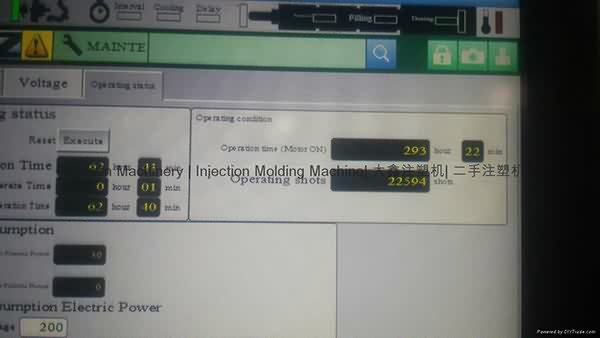

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Super Purchasing for Sumitomo 130t All-Electric used Injection Modling Machine Export to Georgia, The product will supply to all over the world, such as: Paraguay , Cambodia , Swaziland , You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

Làm hết sức, chơi hết mình! ^^

SOLD MACHINE

used Extrusion Blow Moulding Up to 1l Brand: MAGIC Model: MGL 2-3-D Year: 1999

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300027131?opendocument&ln=en&origin=YouTube

Extrusión Soplado Hasta 1 l Usada Marca: MAGIC Modelo: MGL 2-3-D Año: 1999

Macchina Usata: Estrusione soffiagio fino 1lt

Beschreibung der Gebrauchtmaschine: Extrusionsblasformmaschine bis zu 1l

Description de la Machine d'occasion: Extrusion soufflage jusqu'à 1l

Használt gép: Extrudálás Fröccsöntés Blow Up a 1L

Б/У Оборудование:Экструзионно-выдувные машины 1л

Použitý Stroj: Extruze Vyfukovací tvarování až 1 litr

Maszyna używana: Wytłaczarka do 1 litra

Kullanılmış makine: 1 l kadar Ekstrüzyon Şişirme

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.