Top Quality Haitian 160t (servo) used Injection Molding Machine Supply to Kenya

Top Quality Haitian 160t (servo) used Injection Molding Machine Supply to Kenya Detail:

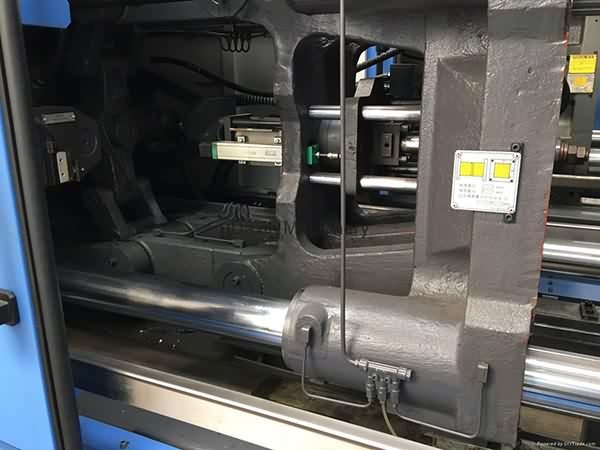

Haitian 160t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for Top Quality Haitian 160t (servo) used Injection Molding Machine Supply to Kenya, The product will supply to all over the world, such as: Jeddah , Kuwait , Japan , We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Amazing Milacron IMM Running with a High-Tech Stacking double cube mold technology "FANTÁSTICO" Injetora Milacron rodando com um Molde de alta ...

nhận sửa khuôn thiết kế chế tạo khuôn ép nhựa. gia công chế tạo chi tiết máy móc cơ khí chính xác cnc1st.com ceocnc1st@gmail.com Chuyên nhận gia công, ...

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!