Top Quality Multiplas 200t (wide platen) Double Colour used Injection Molding Machine for Mauritius Factory

Top Quality Multiplas 200t (wide platen) Double Colour used Injection Molding Machine for Mauritius Factory Detail:

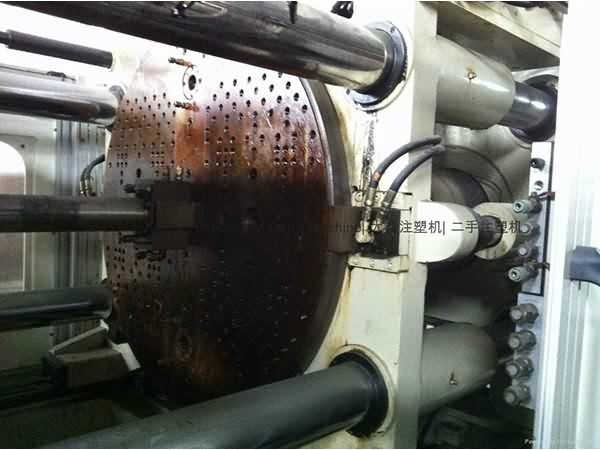

Taiwan Multiplas 200t (wide platen) Double Colour used Plastic Injection Molding Machine

Model: DCM-200T-2C

Clamping force: 200t

Tie bar distance: 940x490mm

Screw diameter(A): 24mm

Shot Weight (A): 60g.

Screw diameter(B): 27mm.

Shot Weight (B): 80g.

Year: 2010.

Motor: 45kw.

Daylight Opening(Max): 800mm.

Machine come with accumulators, two hydraulic clamp tank. It is in very good working condition. It is a much bigger machine that the usual 200t. Interested buyers are welcome to inspect machine anytime.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for Top Quality Multiplas 200t (wide platen) Double Colour used Injection Molding Machine for Mauritius Factory, The product will supply to all over the world, such as: Greece , French , Milan , Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

This is our plastic injection molding object handling robot. The robot is servo driven and is Euromap12 compatible. This robot is Made in Iran by Mexima ...

CERAMIC CUPS & BOWLS AUTOMATIC PRODUCTION LINE.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.