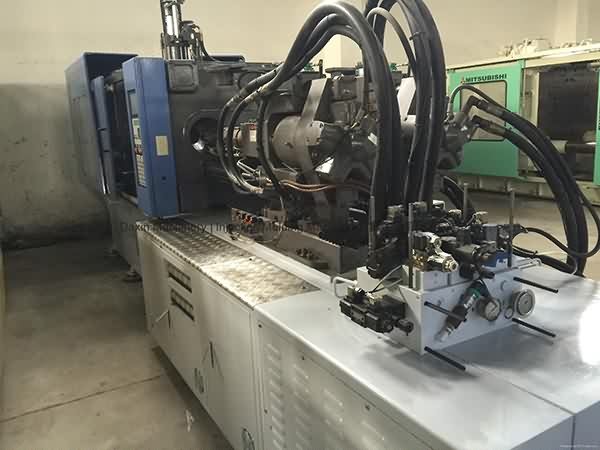

Wholesale Price Hwa Chin 350t double-color used Injection Molding Machine Export to Saudi Arabia

Wholesale Price Hwa Chin 350t double-color used Injection Molding Machine Export to Saudi Arabia Detail:

Taiwa Hwa Chin 350t Double Color used Injection Molding Machine.

Model: DC-350.

Year: 2010.

Screw diameters: 32/32mm.

Tie bar spacing: 650x650mm.

Diameter of rotary table: 950mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

We also present product or service sourcing and flight consolidation products and services. We have our possess manufacturing facility and sourcing place of work. We can easily supply you with almost every type of product or service connected to our item variety for Wholesale Price Hwa Chin 350t double-color used Injection Molding Machine Export to Saudi Arabia, The product will supply to all over the world, such as: Swiss , Belgium , Melbourne , We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Company website: www.cnmolder.com For any suggestion please contact focaremould@yahoo.com Thank you. Lucia.

A new hybrid 3D printing technique developed at the Wyss Institute at Harvard University, Harvard’s John A. Paulson School of Engineering and Applied Sciences, and the Air Force Research Laboratory combines stretchable conductive inks and electronic components into flexible, durable wearable devices that move with the body and offer increased programmability. Credit: Wyss Institute at Harvard University

To learn more, please visit: https://wyss.harvard.edu/low-cost-wearables-manufactured-by-hybrid-3d-printing

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.